SOCKS & STOCKINGS MANUFACTURER IN CHINA

We Provide A Complete Portfolio of Services from Design, Sampling, Procurement, Large-Scale Production, Inspection, Shipping and Customs Clearance.

WHAT WE OFFER↓

LOWER PRICES

Due to the stable cooperation with the raw material suppliers, our factory can purchase fabrics and accessories at the fastest time and the cheapest price. Coupled with large-scale production line, our cost is well controlled.Without the participation of middlemen, our cooperation will be more profitable and more efficient.

FAST RESPONSE

You can provide us with design drafts and requirements, or you can send us samples. Our technician will select the right material to make samples as quickly as possible and express confirmation to you with a very good quote.

MASS PRODUCTION

As we have long-term cooperative relations with several large spinning mills、accessories suppliers、printing and dyeing plants、embroidery factories, etc., we can get the supply of raw materials at the best price in time.Coupled with the scientific management scheduling of our large socks processing plants, you can ensure that your order is completed in a timely manner.

WORLDWIDE SHIPPING

Usually our departure port is Shanghai.If you have your own designated freight agency, we will sign a FOB contract with you, and if you need us to ship the goods to your designated location, we will sign a CIF contract with you. In addition to the advantages of prices, our transportation costs are also advantageous, whether by air or sea.

RECENT ORDERS RECEIVED

-

Mickey Haring Kids Mix Socks

$5.99 -

Spider Man Kids Socks

$7.99 -

Dino Day Socks

$6.99 -

Paradise Falls Kids Socks

$7.99 -

Ultra Tab Socks

$6.99 -

Warbird Socks

$7.99 -

Black Sheep QTR Socks

$12.99 -

Nellis Tab Socks

$6.99 -

Monkey Chillin Socks

$7.99 -

Kirkja Socks

$5.79 -

Tucker Crew Socks

$9.99 -

Spidey Socks

$11.90 -

Genuine Geo Crew Socks

$7.90 -

Jazzy Crew Socks

$7.90 -

The Bounty Socks

$9.99 -

Play Larga Socks

$7.50 -

Women’s Tri-Block QTR Socks

$5.80 -

Women’s Floral Ankle Socks

$8.00 -

Women’s Tie Dye Calf Socks

$8.00 -

Women’s Performance Golf Ankle Socks

$8.00 -

Heart And Sole Calf Socks

$6.00 -

Men’s Lightweight Tie Dye No Shows Sock

$6.80 -

Men’s Tie Dye Calf Socks

$8.00 -

Men’s Merino Wool Ski & Snowboard Socks

$12.00 -

Men’s Performance Cushioned No Show Socks

$8.00 -

Youth Originals Calf Sock

$2.90 -

Men Ribbed Socks

$0.35 -

Men Fire Pattern Socks

$0.65 -

Silicone Non-slip Floor Socks

$1.00 -

Mesh Trim Crew Socks

$1.00 -

Men’s Cotton Socks with Thick Middle Tube

$1.55 -

Women’s Autumn and Winter Wool Knee Warmers

$7.00 -

Small Floral Design Glass Silk Crystal Socks

$2.00 -

Women’s Retro Floral Mid-tube Lace Gold Silk Socks

$4.00 -

Pleated Cotton Socks with Florets in Retro Style

$2.50 -

French Abstract Art Series Retro Cotton Stockings

$1.25 -

Children’s Spring and Autumn Cotton Stockings

$3.90 -

Girl’s Green Forest Series Fresh Short Socks

$1.70 -

Women’s Cotton Retro Preppy Mid-cap Socks

$2.10 -

New Autumn/Winter Jacquard Cotton Socks

$2.00 -

Men’s Business Hose English Style Socks

$3.70 -

Men’s Business Thick Long Socks in Solid Color

$1.75 -

Men’s Medium Tube Socks of Solid Color

$1.90 -

Men’s Cotton Stockings for Spring & Autumn

$1.23 -

Shock Absorbing Long Hose Sports Socks

$0.89 -

Silicone Non-slip Summer Socks for Ladies

$1.50 -

Men’s Cotton Low Tops Socks for Summer

$0.50 -

Cotton Sports Socks for Men

$1.10

Want to Know More?

LET'S TALK

Fill in your info to schedule a time to talk. We Promise not to Use Your E-mail for Spam.

SOMETHING ABOUT SOCKS MANUFACTURER in CHINA

A Socks Manufacturers’ Primer on What You Wear on Your Feet

Summer’s over, and soon winter will be at our doorsteps and through our windows. A drastic shift in what people wear is more pronounced—coats are thicker, sleeves are longer, and shoes are chunkier and heavier. But some changes are not so noticeable. Some things are also changing, quite literally, underneath all that. People are starting to wear longer and thicker socks to deal with the gradually dropping temperatures. Such things are even more significant in areas of cold climates, like in the northern regions.

Socks are an essential part of your wardrobe, whether athletic or casual, no matter the season. This article will talk about some basic ideas and information about how socks manufacturers create and finalize their products.

Socks Manufacturing process

Socks manufacturers follow a complex and multi-stage production process. The first stage in sock-making involves knitting to create a fabric that is elastic, which is a necessary feature for socks. This step also includes adding color or other design elements to create patterns on the socks. Next comes sewing, where the knitted fabric is sewn together into pairs of socks. Finally, the socks are finished by applying finishing touches such as laces, ribbons, buttons, etc.

Let’s elaborate a little bit more about the main stages:

Knitting

Socks manufacturers apply colors either through the choice of yarn that is already dyed or by dying them after knitting. In order for socks to fit properly, they must have enough stretch in them so that when you put your foot inside, it will not feel tight around your leg. To achieve this goal, socks manufacturers use yarns with high percentages of spandex. Spandex allows the knitters to produce more stitches per inch than regular cotton yarn would allow without stretching out too much.

Knitters employed by socks manufacturers usually work from charts or written instructions rather than using their own judgment about how many stitches to cast onto each needle. They may choose to add additional rows at certain points during the knitting process to increase the amount of stitch length. Socks manufacturers also use special machines that follow programmed design specifications.

Stitching and Seaming

Next, the socks are stitched together along seams called gussets. Gusseted socks help keep the toes from rubbing against each other. Socks manufacturers add stitches between the toe and heel areas of the sock to provide support and stability. A seam is created across the top of the ankle portion of the sock to hold the two halves together. Additional seams are often included near the bottom to ensure that no part of the sock falls apart.

Socks manufacturers accomplish seaming by hand or by machine. Hand-sewing requires skillful workers who sew individual seams between every pair of toes. Machine-seaming uses specialized equipment called “footers” to join the toe sections together automatically. Machine-seamed socks tend to cost less for socks manufacturers than handmade ones but take longer to complete. Some people prefer the look of hand-sewn socks, while others find the overall appearance of machine-seamed socks more appealing.

Dyeing and Drying

Dyeing makes the colors of the socks uniform throughout all of the socks produced. Socks manufacturers need the process of washing to remove excess dirt and oils from the socks while keeping them clean. After washing, the socks dry naturally or are placed in special machines designed specifically for drying socks.

Final drying takes place either outside or indoors, depending upon weather conditions. If the socks need to stay warm, then they should be dried outdoors. However, if the socks do not require heat, then they can be dried indoors. In both cases, the socks are hung up to air dry. Once the socks are completely dry, they are packaged and readied by socks manufacturers for shipping.

Shaping

The socks go through what socks manufacturers call the “boarding process.” It involves steaming and stretching to form the right shapes and sizes. Pressing is also done to get the nice flat and smooth look we see in brand new socks. After that, socks manufacturers pair them up and prepare them for packaging and shipping.

Fabrics used by socks manufacturers

Socks manufacturers use three main types of materials: natural fibers, synthetic fibers, and blends of these two. Natural fiber socks are made primarily from cotton. Cotton has been one of the most popular choices for socks manufacturers since its introduction as an alternative to wool because it provides warmth, comfort, and breathability. It does not shrink easily and resists pilling. Synthetic fibers such as polyester offer similar benefits, including durability and resistance to moisture absorption.

In order for socks to fit properly, socks manufacturers must ensure that they have enough stretch in them so that when you put your foot inside, it will not feel tight around your ankle. To achieve this goal, socks manufacturers use yarns with high amounts of elasticity. These types of yarns include cotton/polyester blends, nylon, polypropylene, spandex, Lycra® brand fibers, and others.

Wicking

When choosing socks, consider whether wicking properties matter to you. Wicking refers to the removal of moisture through the capillary process. Socks manufacturers add wicks into their products to make sure there is adequate airflow under the foot. The purpose of adding wick material is to allow sweat to evaporate away from the skin without causing discomfort. There are different kinds of wicking materials used in socks. They range from cotton to rayon to bamboo. Rayon is considered the best choice due to its ability to absorb water quickly and release it slowly.

Bamboo socks

As the name suggests, socks manufacturers use woven fibers derived from bamboo combined with other materials to create the fabric. These socks are very comfortable and pleasant on the skin; plus, they possess antibacterial properties. The result is a special material that is highly absorbent and effectively helps keep the feet dry.

Cotton socks

Cotton is the most common material used by socks manufacturers. Its softness allows people to wear it comfortably. But, it doesn’t provide much support. So, cotton socks tend to slip down during exercise. Also, cotton absorbs sweat well but dries out fast. Therefore, it’s vital to change socks frequently.

Nylon socks

Nylon socks are durable yet flexible and last a long time. Their moisture-absorbing capability is also excellent. However, nylon socks do not breathe like cotton or bamboo. If you work up a good sweat while wearing nylons, you may experience chafing. Socks manufacturers usually employ this material for formal or dress socks, which makes sense because you are normally not expected to do extensive physical movements while wearing them.

Polyester socks

Polyesters are commonly found in the material for athletic clothing. Because of their strength and flexibility, wearing them the whole day would generally not be uncomfortable. Unlike cotton, which tends to wrinkle after being washed, socks manufacturers have observed that polyester remains clean and crisp.

Acrylic socks

Acrylic socks are light and have very good wicking capability, meaning it does not absorb a lot of moisture and instead takes it away from the foot.

Spandex socks

The most popular kind of sock today is made using Spandex fiber. Spandex is an elastomeric polymer that provides exceptional comfort and durability. Socks manufacturers often blend spandex with natural fibers such as wool, silk, cashmere, and cotton.

Silk socks

Silk is renowned for its smoothness, and it is why it is used to make luxurious socks. Its tensile strength is high, thereby making the socks more durable.

Wool socks

Next to cotton, wool is the second-most common material used by socks manufacturers. Excellent breathability and insulation are the main characteristics that make them suitable for socks.

Cashmere socks

Cashmere is very similar to wool, so socks manufacturers have also started using it. But because of its more premium softness and other qualities, it is much more expensive. Cashmere socks are considered luxury garments and are very trendy these days.

Sock types according to use

There are many different types of socks available. Some are designed specifically for certain activities. Some are meant to be casual everyday wear. Here are just a few examples:

Athletic socks

– Designed for running, walking, hiking, biking, etc., athletic socks help prevent blisters by keeping the feet warm and dry. Lycra® brand socks are usually worn by athletes who want to stay cool and dry because they are extremely thin and keep air circulating between the skin and the sock.

Dress socks

– For formal occasions, these are generally matched with the color of the suit, especially the pants. Black, gray, and brown are common choices for these socks.

Casual socks

– Made for daily wear, casual socks come in various styles and colors. They also feature ventilation holes to promote airflow between the toes and heels.

Compression socks

– This type of socks is usually worn over regular socks to reduce swelling caused by varicose veins, edema, leg cramps, and shin splints.

Sock lengths

As with use, socks manufacturers also produce this type of hosiery in varied lengths. Apart from functionality, sock lengths are also essential in creating your style or for simply matching outfits. Here are some of the common types:

Ankle socks

– As the name suggests, these socks reach only up to the ankle. These are typically worn in sports and fitness activities.

Crew socks

– The most traditional type, these extend up the middle of the calf or about 6-8 inches from the heel to the top. It usually has in the opening and is great for everyday use.

Mid-calf socks

– These go up a bit higher than typical crew socks. They are usually made with thinner fabrics. These are also sometimes called trouser socks because they are the usual choice to go with office wear.

Knee highs

– These fully cover the calves and go right up to just below the knee.

Over-the-knee socks

– They are often matched with short skirts because they go up just above the knees.

Thigh highs

– Even bolder than over-the-knee socks, thigh highs reach up to the thigh. They usually have a tight elastic band at the top to hold them up.

No-show socks

– This type provides the “no sock” look but still offers the protection that socks give to the feet. Because they’re practically unseen, women usually wear them with flats and then boat shoes for men.

Toe cover socks

– The shortest among all sock types, these cover just half of the length of the feet – from the toes to midfoot. These are best for slip-on footwear, so that’s why they’re also called “mule socks.”

Special styles

Socks can also be classified according to particular design characteristics and how they are worn. For these, socks manufacturers apply certain adjustments and modifications in their process, especially in the sewing stage. Here are some examples:

Tube socks

– Manufactured a bit differently, these have no shaped heels to allow the use with any foot length or size.

Tabi socks

– Originally worn by the Japanese, especially when wearing Kimonos, the big toes are separated from the rest, making them perfect for use with slippers.

Toe socks

– This style is a little similar to tabi socks, except that all the toes are separated. This design is said to be very advantageous in keeping most of the feet warm during the winter. The overall look also earned its other name, “glove socks.”

Toeless socks

– This time, all the toes are exposed because the tip is not closed. The opening allows the toes more movement, which makes these a choice for dancing and yoga.

Loose socks

– Another style that came from Japan, these are usually as long as thigh highs but are loose or baggy. However, instead of worn pulled-up the leg, these are pushed down towards the ankle, creating a thick, bundled look.

So these are some of the practical information and ideas about the activities and products of socks manufacturers. These details can be helpful in your choice of the appropriate type of socks for varied activities. Socks manufacturers carefully study and implement design and material details in producing each kind. By all means, you can go with any colors and patterns you desire in order to express your style and personality. Just consider the presentation here to guide on the practical considerations for your choices for socks.

A Quick Peek Inside a Socks Factory

Socks are essential for every man’s wardrobe. They provide the feet warmth, comfort, and protection from the elements. But did you know that socks also play a vital role in our health? Sock manufacturers are now using their expertise in materials science to create innovative new products that promote good foot health.

Socks are worn by practically billions of people each day. From athletic wear to casual footwear, socks come in a variety of styles and colors. The average person wears around 100 pairs of socks per year.

Socks are often overlooked as part of a healthy lifestyle. But they can improve your overall well-being. In fact, study results have shown that wearing socks can reduce stress levels, lower blood pressure, and even prevent heart disease.

The benefits of wearing socks are endless. So when the time to replace those old or damaged pairs has come, make sure you choose quality socks made with high-tech fabrics that will keep up with your active lifestyle.

Let’s look at some fascinating facts and information about socks and how they are put together in a socks factory.

Sock-making origins

Socks have mirrored shifting styles and civilizations and the shape of the individuals who wear them throughout history. While key figures in modern history’s socks are practically never given attention or discussed, you can imagine how significant the act of putting on socks in the morning could have been for them. Though with a great deal of imagination, it can be argued that these individuals’ comfort and bearing as they played were influenced by the socks they wore.

But in all seriousness, the industry involving socks manufacturing and how a socks factory came to be is part of the evolution of craft, economics, and lifestyle throughout the centuries.

Just for some trivia, it would be interesting to point out that the word “sock” derives from the Anglo-Saxon word hossan, which means “to cover the entire leg.” Hossa discovered a pair of light pants. Also, originally, “stocking” meant “drain” or “stump,” while “reserve” meant “limit” or “fence” in Anglo-Saxon.

How does a sock factory operate?

A socks factory can be categorized as small-scale or large-scale. A small-scale socks factory produces fewer than 100 pairs every hour. Sewing each pair of socks is generally done by hand in a socks factory. For a large-scale socks factory, over 1,000 pairs can be produced every hour.

The manufacturing lines in a socks factory are equipped with automated sewing machines, allowing them to enhance their output significantly. Both systems have advantages and disadvantages. A small-scale socks factory, for example, tends to provide greater value for money since they are less expensive to set up. On the other hand, a large-scale socks factory demands a bigger initial investment.

Furthermore, these approaches have various hazards attached to them. A small-scale socks factory, for example, frequently uses unskilled employees who lack training and expertise. As a result, it creates the risk of damaging the cloth during the stitching process. However, a large-scale socks factory often engages qualified specialists who must complete lengthy training before being permitted to execute certain duties. This ensures that the process runs smoothly at all times.

What goes on in a socks factory?

Here is a brief rundown of how work is done in a socks factory.

Materials Selection

Selecting the right fabric is a crucial step in making great socks.

Designing

A designer creates a pattern based on the client’s needs. This may include choosing a color scheme, design patterns, and other details.

Cutting

The sock maker cuts out the pieces needed to make the final product.

Sewing

The sock maker attaches all the components together. They then use different techniques like knitting, weaving, or sewing to complete the job.

Finishing

After stitching, the sock maker applies any finishing touches to the work before packaging and shipping it off.

Quality Control

Once the socks reach the customer, the quality control team checks them for defects.

Packaging

The finished socks go through quality control one more time before being packaged and shipped.

What is boarding and why is it important in a socks factory?

After being cleaned and dried, the socks are taken to the board matching area. They are then pushed onto flat metal foot forms (called boarding) and molded into the desired shape and size. They are then steam-pressed to get their final flat, tidy shapes. When this is completed, they are ready to be partnered. Even socks made on the same machine with the same yarn and settings might differ significantly, thus the matching procedure is critical to avoiding difficulties during distribution. The final phase in this process is a rigorous quality review. The finished product is thoroughly verified, and any errors are traced back to the production process and repaired.

Materials used by a socks factory for production

There have been tremendous advances in fabric production and varieties these past few years. You will surely find a wide range of materials used in production in a socks factory. However, some fabrics are tried-and-tested for socks, and here are some of them:

Cotton

Because of its softness, this natural fiber is the most commonly used for production in a socks factory. It offers good breathability, but nylon is usually added to improve durability in socks.

Wool

Wool is the second-most common fabric used by a socks factory. The major characteristics that make them suitable for socks are their excellent breathability and insulation, helping to keep your feet dry and warm.

Spandex

Spandex is a kind of elastomer that is both comfortable and long-lasting. Spandex is frequently used with natural fibers including wool, silk, cashmere, and cotton in a socks factory’s production.

Nylon

Nylon socks last a long time yet are flexible and weigh very little. The ability to absorb moisture is also why they are among the primary raw materials used in a socks factory. Unlike cotton, though, nylon does not allow air to pass as well as cotton.

Polyester

Strong and flexible, this material is often used in athleisure wear. This also has an excellent wrinkle-resistance capability.

Silk

Silk is luxurious. It is very smooth and elegant-looking. It has the remarkable property of being stretched or pulled without easily breaking or wearing out. This helps make socks more durable, thereby prolonging their stay in one’s regular wardrobe.

Bamboo

One of the latest innovations, bamboo fiber, makes for very soft fabrics. Because the material is very absorbent, they help keep the feet dry and helps prevent bacteria growth.

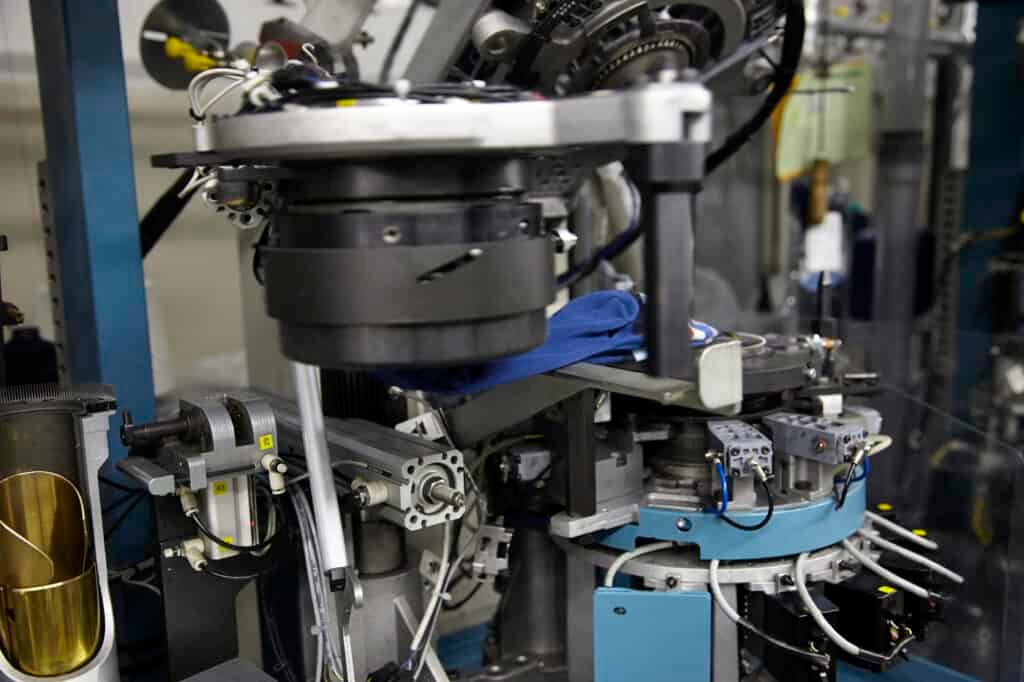

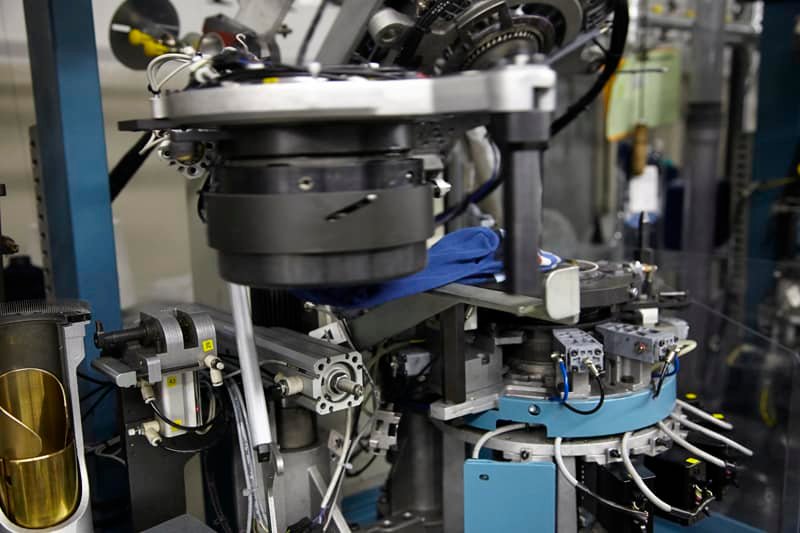

Workhorses of a socks factory

Knitting Machines

While the raw materials like threads and fibers may be the same in many garments, the fabric needed in a socks factory is produced specially for socks.

People can knit personal socks at home. It’s a pretty popular hobby for a number of people. However, a circular knitting machine is utilized to put together socks in a socks factory. So what is a knitting machine?

The workhorses in a socks factory are called sock knitting machines. These machines are highly specialized circular knitting machines commonly used for products with specific customized specifications. Whatever the form, size, or targeted use may be, this equipment can churn out socks from any kind of material.

Composition

Regardless of where the yarn supply or creel may be located, the same circular knitting concept is observed. The yarn is supplied from the top of the knitting section, stops motion control on the machine, and is returned to the knitting element via tension control and thread feed system. High-quality products can only be manufactured by properly configuring the stop motion and how the thread is provided. The sewing machine conducts the knitting in the center. This happens between the take-up reel and the feed section, at intervals where the needles create stitches. In circular knitting, the process occurs one after another, around the cylinder, and tubes are made to produce horizontal stitches.

Cylinder

All the stitches needed to make socks are done on the cylinder of a single-cylinder machine with vertical needles. Dials with cylinders, hands, sinkers, and transfer mechanisms form the framework of the entire machine.

Process of the Knitting Needle

The sock knitting needle should create a fresh stitch, thread it through what has already been formed, loosen the last seam and allow the new stitch to stretch to the intended length of the result. By changing this cycle, you can fine-tune the texture, appearance, and performance of your product to accommodate stress. Tweaking certain aspects, appearance, and performance according to requirements can be done through certain modifications on the cycle.

Machine types in a sock factory

Sock material is created with a single group of needles. Doubling the batch of needles results in double-knit textiles.

Some machines in the sock factory have a double cylinder with one position directly on top of the opposition to form a link.

There are various machines programmed for selected tasks. Some give a reinforcement, build pockets, line the inside of socks, and make other improvements.

Color dyeing and the finishing process

Another set of key steps in the production process in a socks factory is dyeing and finishing. Like all garments, color designs and applications require certain actions. In the case of a socks factory, the application of dye colors is highly similar to what is done to other clothing. The same ideas are pursued in the steps to finishing the product. The only difference is that socks made with selected colored yarns no longer need to be not subjected to more dyeing. In any case, this process to finish socks is as essential as for other garments.

Rotary drum machine

This machine works by tumbling the materials inside to avoid indirect contact with heating elements. In sock dyeing, this type of machine is efficient because of the low consumption of water, energy, and chemicals. It also offers quicker treatment times. It is automated through a computerized system that facilitates the process, including the addition of treating materials.

Paddle machines

For this type of equipment, socks are mobilized, pushed, and agitated inside containers by paddles that are rotating. The movement ushers the socks and essentially pushes them into the tub. The large capacity makes them ideal to use for cleaning and bleaching. The downside to this machine is the amount of large consumption and costs in energy and resources. And even with utilization, work takes significantly longer.

Removal

The socks are pulled out after the wet treatment in order to eliminate the excess water. This is done by force by subjecting them to a rotary machine that does the job quickly and efficiently.

Dryer

Tumble drying also helps condition the socks to minimize shrinkage, which is why any socks factory prefers it. It is also normal for a sock factory to connect these systems to the rest of the finishing machines.

Scrub and bleach

In the operations of a socks factory, the dyeing machines have continuous tube lines that scour and bleach the products. These are extremely useful because they can work non-stop and require less manpower but at the same time have a large working capacity.

Dyeing

Adding color to threads, yarns, and fabrics is a significant part of garment manufacturing. Again, color can be added to the products through selected yarns and materials or dyes applied after. In a socks factory, debris, excess fabrics, and material must be removed before applying the dye. Bleaching, meanwhile, is necessary for prepping cotton socks before dyeing.

Finishing

In clothing production, the term “to finish” a color means to treat the textile or garment to allow the qualities and characteristics of the color to come out. Quite naturally, this is often the concluding step of production.

Boarding

In a socks factory, the “boarding” process involves the application of heat, particularly in the form of steam to press the socks into form. This is an important step in packing and retaining the form of the socks. Settings are adjusted accordingly to process particular fabrics like blends, spandex, polyester, etc. The sudden application of high heat will help the sock “remember” and keep the boarded shape, and it will help prevent the item from shrinking, especially when washed.

Conclusion

With this presentation of facts and explanations, you can further appreciate the soft, reassuring garment covering your feet and toes. Anyone planning to develop their socks brand will benefit from this piece because it will help them understand what goes on in a socks factory.

Taking a Step Forward with Customer Sock Manufacturers

No matter the personality, people find ways to express their thoughts, feelings, moods, and philosophies in different ways. Fashion is arguably the most popular way. Through clothing, individuals can share part of their personality in either a subtle or ostentatious manner.

One type of clothing is often overlooked or unnoticed but is getting more and more popular as a showcase piece for expression. Because these are often hidden or covered by trousers and shoes, socks barely get the light of day. Of course, they can also be proudly displayed when wearing shorts, cropped pants, and ankle pants.

So, there is undoubtedly a market now for socks that go beyond the traditional white, black, and gray color range. People, young and old, are now on the lookout for socks that are hip, funky, stylish, and even quirky enough to be cool. Stripes, argyle, and traditional prints are not enough. If you have creative skills in the visual arts and are keen on creating designs for socks, you can start a small business out of it. When you’re clear on what you want to do, then you can start looking at custom sock manufacturers you can work with.

So this article will talk about socks, especially how to choose custom sock manufacturers. This text will lay out basic information and ideas to help you decide if you wish to proceed with this endeavor and how you should go about it.

Searching for Custom Sock Manufacturers

There are different ways to look for custom sock manufacturers. The easiest would be to search online. It is convenient because usually, the search results start with those nearest you. List down names you think would be worth looking into and check if they have websites for further info.

Another way to scout potential custom sock manufacturers is to check out trade fairs and exhibitions. This allows you the opportunity to talk to some of their representatives and personally look at some of their work.

You can try some groups and forums to collect names of custom sock manufacturers and even get some reviews and shared experiences from their clients.

When you have narrowed down a shortlist of custom sock manufacturers, you need to get as much info as possible about their operations, business model, and how they deal with customers.

How to Decide on a Custom Sock Manufacturer

Custom sock manufacturers, first and foremost, must have expertise in producing socks. The next critical aspect that should be clarified is how they go about their customization. It goes without saying that cost and quality are essential points, but other things also need highlighting.

Here are a few points that should also be taken into account in selecting custom sock manufacturers:

Design Assistance

More and more custom socks manufacturers provide initial free assistance in finalizing designs. Designs on paper would not come out exactly the same on socks and other garments. It will give you the chance to make necessary adjustments before production begins.

Full Customization

How much freedom do custom sock manufacturers allow? It must be clear if you can only modify certain aspects of their standard styles and construction. Are they capable and flexible enough to assist you with complete customization? It depends, of course, on what designs you have planned. There will likely be minimal issues if your design is purely a print or color job. Custom sock manufacturers should be ready to adapt to such modifications.

Production Capability

If your needs involve large volumes, take note of the different custom sock manufacturers’ production capacities. This will help you avoid being left hanging when fulfilling orders. Ask for examples of orders from past clients to see how experienced the custom sock manufacturers are when dealing with large orders.

Scheduling and Turnaround Time

Compare how your shortlisted custom sock manufacturers plan their operations for customized products. Determine which one offers a turnaround time that will suit your plans. Deadlines, targets, delivery dates, and other matters should be clear to both parties.

Quality and materials

You may have a great design idea, but can you determine which one can execute it the way you want? Study the samples and materials your shortlisted custom sock manufacturers use, and take note of their strengths and weaknesses. Also, necessary in this time and age, to find out if sustainable and eco-friendly fabrics and materials are employed. Please take a good look at some of their samples and see how well they utilized the fabrics.

Regulation and Certification

There should be no questions about the reputation of the pool of custom sock manufacturers from which you will select. In particular, you should end up with a choice of a company that complies with government regulations and strives for certification in the fields of quality, environment, safety, and ethics. It would be safe to expect excellence in products from custom sock manufacturers who aspire to high levels of quality and professionalism.

Customer Support and Communication

Custom sock manufacturers must make it a point to be easy to reach and communicate with throughout the process. The who and how of communicating issues and urgent information must be clearly and formally set. If, for example, the transaction is fulfilled through a website or online platform, there should be active hotlines, helpdesks, and direct emails provided.

Shipping Arrangements and Costs

This is one of the points where custom sock manufacturers offer benefits and deals in contracts. Some may offer free shipping for a certain minimum number of orders. Other perks and benefits may also be discussed, but make sure it does not affect your own business schedule. Try to evaluate the process and fee they set for shipping if it is worth it.

Determining the Details

When you’ve already combed through the pool of custom sock manufacturers, you need to make decisions on your own end. Below are some points you should have already decided on when moving forward with your choice among custom sock manufacturers.

Type/Usage

Decide on which activities or occasions your design ideas will work best. Here are some of the general types of socks you can select from:

Sports/Athletic socks

These socks are traditionally constructed thicker and are designed to accommodate all the wearer’s movements while playing. The fabric choice is critical because it should prevent blisters with all the shuffling and rubbing of the feet and shoes. Especially for sports like football, socks should be high enough and stay in place to provide a shield for the shin, calves, and ankles. Custom sock manufacturers can print or embroider team emblems or unique designs.

Compression socks

These socks are primarily used for dealing with medical conditions like Deep Vein Thrombosis (DVT), edema, and other problems related to blood circulation. They are very snug and gently squeeze or compress the legs. Improved blood circulation is why athletes also use this type of socks.

Dress and casual socks

These socks are generally not shown unless the wearer sits and the pant legs ride up to expose the ankle area. These socks are worn for work and daily activities in terms of occasion. Because they are typically mid-calf in length, it is common for them to slide down soon after they’re worn and pulled up. For formal and business attire, dress socks come in dark colors like black and gray in terms of design. Sometimes they would have subtle little printed or embroidered details. Casual socks for work or going out can be more ornate and bold. Typical designs would be argyle and assorted prints. Custom sock manufacturers can help you determine the best way to execute your designs to make them truly special.

Novelty socks

These specially-produced socks are for special occasions. If you want to make Christmas, Halloween, and other holidays special, these can add some quirkiness and fun. Even if there are no special events, you can have custom sock manufacturers produce special statement items or originally designed socks for you. Pop culture themes, images, and references are in demand these days. These socks can really help express one’s overall vibe and personality.

Length

Visualize if your designs will work or not on long or short socks. Custom sock manufacturers should be able to explain in specific detail the sock length specifications they are capable of producing. Here is a simplified guide on a few types of standard lengths for socks:

No-show socks

These socks are hidden, so it’s usually worn by women who wear flat shoes. These are also popular for those who want the no-sock look when wearing sneakers.

Ankle socks

These go only up as high as the ankles. Commonly used in sports, these are also worn with casual wear.

Crew socks

This type is what is generally considered the standard length of socks. Most of the time, custom sock manufacturers make them at about 6 to 8 inches high, starting from the heel.

Knee-high socks

These normally go between 13 and 15 inches high, right up to the knees for adults. These socks offer a lot of space for designs for custom sock manufacturers to work with, including logos on the upper part.

Over-the-knee socks

Very popularly matched with skirts, these go a few inches past the kneecaps, up to the lower part of the thigh. These socks accentuate the sexiness of the legs’ shape, so the custom sock manufacturers know that the design must complement that.

Fabric and Materials

Cotton

Cotton is the top choice for clothing, including socks. It is soft and comfortable and has excellent moisture-absorbing characteristics. When blended with nylon, the fabric improves durability and moisture-wicking capability. Socks made of 100% cotton would not be a good choice for sports because all the moisture retained would be uncomfortable to the skin.

Nylon

Lightweight yet very durable, it works well when combined with other fibers, including cotton. Sock makers also recognize how well nylon fibers can dry off moisture. Another remarkable quality of nylon is that it is very elastic.

Polyester

This synthetic fiber is known for its durability in the face of wear and tear. In terms of color, they last longer compared to cotton. Sock manufacturers use this material for athletic socks because they are quick-drying and wrinkle-resistant.

Spandex or Lycra

The development of spandex has had a significant impact on clothes, especially on sports and activewear. This material offers excellent elasticity comparable to rubber. It provides clothing flexibility and durability. In the case of socks, it gives comfort and helps them from sliding down the leg and offering extra support.

Wool

Wool is known for its excellent insulating characteristic, so it’s great for winter socks. It has an excellent moisture-absorbing capability, making it great for hiking socks. A type of high-quality type of wool that is sought after for its incredible softness and luxurious comfort is Merino wool.

Silk

One of the most popular luxurious fabrics, silk is renowned for its smoothness. However, its fibers also have excellent moisture-absorbing capabilities. Not only that, it provides excellent insulation and is very durable.

Bamboo

This material is growing more and more in popularity. Fiber from bamboo plants is processed into fabrics for clothes, including socks. Bamboo fiber makes for very smooth fabrics and is hypoallergenic. Not only that, it has antibacterial properties that can prevent skin problems caused by germs and bacteria.

Rayon

Rayon is manufactured using cellulose taken from the pulp of different trees, such as bamboo, eucalyptus, and others. It is known for its softness and moisture absorption. Rayon also contributes a gloss or shine to the fabric. However, it does not have the same level of durability as other fabrics, especially after many washes and drying.

Modal

Modal is a variety of rayon that is made from beech tree pulp. This semi-synthetic material is expensive. It is usually blended with other fibers, resulting in a highly durable and very soft fabric.

Ready to Proceed

So, once your business plan is ready and clear on your designs, you are set to discuss your choice among custom sock manufacturers formally. Your vision must be clear about your business plans and how your product should come out. You should have clear expectations concerning how your custom socks look and feel. You and your manufacturer must understand and have a clear vision about the whole endeavor to create beautiful socks that people will love.

Quick Guide

Want to Know More?

LET'S TALK

Fill in your info to schedule a time to talk. We Promise not to Use Your E-mail for Spam.