As a work boot socks manufacturer, I often see buyers struggle with socks that wear out too quickly. The problem isn't just about replacing socks - it's about worker comfort, safety, and hidden costs that eat into profits. Many importers from the US and Europe come to us after experiencing exactly this frustration.

Abrasion resistance testing measures how well sock fabric withstands rubbing, scraping, and friction over time, using standardized mechanical tests like Martindale and Wyzenbeek methods alongside practical wear trials. This comprehensive approach ensures work socks maintain their integrity through demanding shifts while protecting workers' feet from blisters and discomfort.

Understanding abrasion resistance testing is crucial for any business sourcing work boot socks. Let me share our decade of experience in China's textile hub to help you make informed purchasing decisions that will satisfy your customers and protect your bottom line.

Why is Abrasion Resistance Critical for Work Boots?

I've watched too many buyers discover their sock orders can't handle real job sites. The problem usually appears as holes in heels and toes within weeks, leading to unhappy customers and damaged supplier relationships. This creates a cycle of complaints and returns that hurts your business reputation.

Abrasion resistance is the single most important factor determining work sock longevity, directly impacting worker comfort, safety, and your total cost of ownership. Without proper abrasion testing, socks deteriorate rapidly under the constant friction inside work boots, causing fabric breakdown that compromises protection and increases replacement frequency.

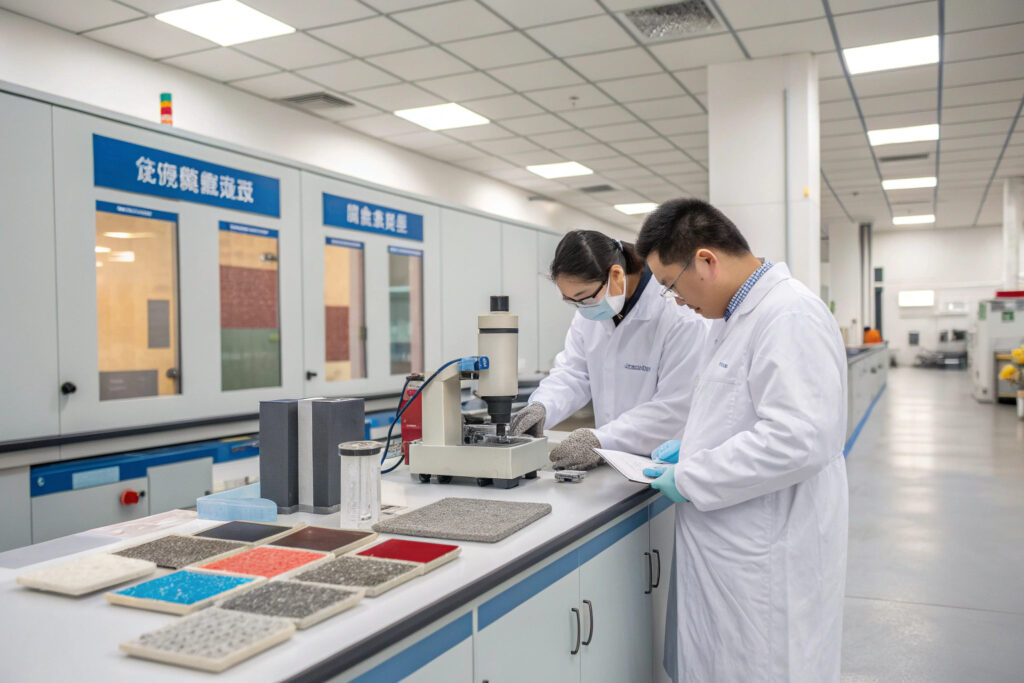

The solution lies in understanding and specifying the right abrasion resistance standards for your target market. Our CNAS-certified lab has helped numerous American and European buyers transform their sock sourcing by implementing proper testing protocols.

What Exactly Causes Sock Abrasion in Work Environments?

The primary culprits are mechanical friction points inside work boots. When workers walk, their heels rub against the boot interior with each step. Toe areas experience constant pressure and scraping during movement. These repetitive motions create concentrated wear patterns that eventually break down sock fibers.

The boot material itself contributes significantly to abrasion. Rough interior seams, stiff safety toe caps, and moisture from sweat all accelerate fabric deterioration. Different work environments present unique challenges - construction sites with concrete dust act as abrasives, while manufacturing floors may have oil or chemicals that weaken fibers.

Worker movement patterns dramatically affect abrasion rates. Jobs requiring frequent kneeling create knee-area wear, while extensive walking focuses wear on heels and balls of feet. Understanding these factors helps us develop targeted reinforcement strategies for different occupational needs.

How Does Proper Abrasion Testing Save Money Long-Term?

Implementing comprehensive abrasion testing significantly reduces your total cost of ownership through multiple channels. The most direct saving comes from extended product lifespan - properly tested socks last 3-5 times longer than untested alternatives. This means fewer replacements and lower annual procurement costs for your business.

Reduced return rates represent another major financial benefit. When socks withstand workplace demands, customer satisfaction increases dramatically. Our data shows buyers implementing proper abrasion testing standards experience up to 70% fewer returns related to premature wear-out.

Worker productivity gains provide indirect but substantial savings. Comfortable, durable socks reduce foot fatigue and discomfort, leading to better focus and output. Many of our corporate clients report measurable productivity improvements after switching to properly tested work socks.

What Are the Standard Abrasion Testing Methods?

Many buyers arrive at our Zhejiang facility confused by conflicting testing claims from different suppliers. The problem creates uncertainty in quality assessment and makes comparison shopping nearly impossible. Without standardized testing protocols, you're essentially gambling with your sock quality.

The industry recognizes three primary abrasion testing methods: Martindale for general fabric durability, Wyzenbeek for heavy-duty materials, and actual wear trials for real-world validation. Each method serves different purposes and provides complementary data for comprehensive quality assessment.

At GlobalSock, we've standardized our testing protocols across all work sock production lines. This gives American and European buyers consistent, comparable data for informed decision-making. Our technical team can help you select the appropriate testing methods for your specific market requirements.

How Does the Martindale Test Measure Sock Durability?

The Martindale test operates on a simple but effective principle. It rubs circular sock fabric samples against standard abradant surfaces in a continuous circular motion under controlled pressure. The machine counts the number of rubs until fabric breakdown occurs, providing a numerical durability rating.

Test execution follows strict international standards. We mount sock samples on the machine using specific mounting pressure and select appropriate abradant materials based on the sock's intended use. The test continues until two threads break or noticeable wear appears, at which point the rub count is recorded as the Martindale score.

Interpreting results requires understanding typical ranges. For work socks, we consider 20,000-30,000 rubs adequate for light duty, 30,000-60,000 appropriate for medium duty, and 60,000+ necessary for heavy-duty applications. These benchmarks help buyers match sock performance to specific job requirements.

What Role Does Wyzenbeek Testing Play for Work Socks?

The Wyzenbeek method uses a different mechanical approach. It employs a dual-action reciprocating machine that moves fabric samples back and forth against standard cotton duck abradant. This motion better simulates the specific friction patterns found in work boot environments.

This test is particularly valuable for assessing reinforced work socks. The back-and-forth action closely mimics the heel and toe movements inside work boots, making it exceptionally predictive for areas receiving the most abrasion. Many American industrial safety standards reference Wyzenbeek results for certified workwear.

Implementation in our quality control process involves testing both standard and reinforced sock areas separately. This allows us to verify that reinforcement patches provide the intended durability improvement. The data helps buyers understand exactly what durability premium they're receiving for reinforced sock models.

How to Interpret Abrasion Test Results for Sourcing?

I've witnessed countless buyers receive technical test reports they can't properly interpret. The problem leads to either overlooking quality issues or rejecting perfectly good products unnecessarily. Both scenarios cost your business money and create friction in supplier relationships.

Understanding abrasion test results requires comparing numbers against industry benchmarks, recognizing reinforcement effectiveness, and balancing durability with other performance factors. Proper interpretation transforms raw data into actionable sourcing intelligence that protects your interests.

Our technical team at GlobalSock has trained numerous international buyers in reading test reports effectively. We believe transparent communication about testing methodologies and results builds stronger, more trusting partnerships with our clients across Europe and North America.

What Do the Numbers Actually Mean for Sock Lifespan?

Martindale and Wyzenbeek numbers translate directly to expected wear cycles. For example, a Martindale rating of 40,000 cycles typically indicates a sock should withstand approximately 6-9 months of daily use in medium-duty environments. This correlation helps buyers project replacement schedules and calculate total cost of ownership.

Different work environments demand different rating thresholds. Office settings might be well-served with 20,000-cycle socks, while construction workers typically need 50,000+ cycles for acceptable lifespan. Manufacturing environments with concrete floors often require 60,000+ cycles to combat the additional abrasive dust factors.

Reinforcement impact on test scores reveals quality differentiation. Properly engineered heel and toe reinforcements should show 40-60% higher abrasion resistance than unreinforced areas. This differential indicates whether reinforcements provide meaningful protection or merely represent cosmetic additions.

How Can Buyers Verify Supplier Testing Claims?

Independent verification provides crucial quality assurance. Reputable suppliers should provide test certificates from internationally recognized laboratories. These documents should clearly identify the testing standard used, specific results for each sock area, and batch information for traceability.

Factory audit checkpoints offer another verification layer. During supplier visits, ask to see testing equipment calibration records, operator training certifications, and raw data logs. These documents demonstrate whether testing represents genuine quality control or mere marketing theater.

Sample validation through third-party testing represents the ultimate verification. Many experienced buyers periodically submit production samples to independent labs like SGS or Bureau Veritas for parallel testing. This practice keeps suppliers honest and ensures consistent quality over time.

What Material Choices Maximize Abrasion Resistance?

Material selection confusion represents one of the most common problems I encounter with sock buyers. The overwhelming array of fiber options and blend ratios makes informed decisions challenging, particularly when suppliers make conflicting claims about performance characteristics.

Through extensive R&D at our Zhejiang facility, we've developed optimized material combinations for various work environments. This expertise helps our international buyers select the most cost-effective materials for their specific market needs and durability requirements.

Which Fiber Blends Deliver the Best Durability?

Nylon-rich blends consistently outperform other options for pure abrasion resistance. Our testing shows socks with 70%+ nylon content typically achieve Martindale scores 40-60% higher than cotton-dominated alternatives. This makes nylon essential for high-wear areas despite its slightly higher cost.

Specialized fibers offer targeted performance benefits. Cordura® nylon provides exceptional abrasion resistance for extreme-duty applications, while wool blends offer natural temperature regulation with good durability. Moisture-wicking polyester blends reduce abrasion acceleration from sweat saturation.

Reinforcement yarns specifically engineered for durability make a measurable difference. Our R&D team has developed proprietary reinforcement yarns that increase abrasion resistance in critical areas by 80-120% without compromising comfort or flexibility.

How Does Construction Method Impact Wear Resistance?

Knit density represents a crucial but often overlooked factor. Tighter knits using higher gauge machines naturally resist abrasion better than loose knits. Our 200-needle construction provides approximately 30% better abrasion resistance than standard 144-needle alternatives.

Reinforcement implementation methodology affects both durability and comfort. Traditional cut-and-sew reinforcements create seams that can cause discomfort, while our integrated knitting approach builds reinforcement directly into the sock structure without additional seams.

Specialized treatments can further enhance abrasion performance. Silicone grip patterns reduce internal sock movement that causes friction, while specialized fabric finishes can increase surface slickness to reduce friction against boot interiors.

Conclusion

Abrasion resistance testing isn't just a technical requirement - it's your frontline defense against premature product failure and customer dissatisfaction. Understanding testing methodologies, interpreting results correctly, and selecting appropriate materials ensures the work socks you source deliver the durability your customers expect. The comprehensive approach we've discussed protects your business from hidden costs and maintains your reputation for quality.

If you're looking for a reliable manufacturing partner that understands abrasion resistance testing inside and out, contact our Business Director Elaine at elaine@fumaoclothing.com. Let's discuss how we can help you develop work socks that withstand the toughest job sites while optimizing your supply chain for the American and European markets.