Creating a perfect tech pack can feel overwhelming. Many brands struggle with unclear instructions, leading to production errors, wasted time, and cost overruns. A well-defined tech pack is your first defense against these issues.

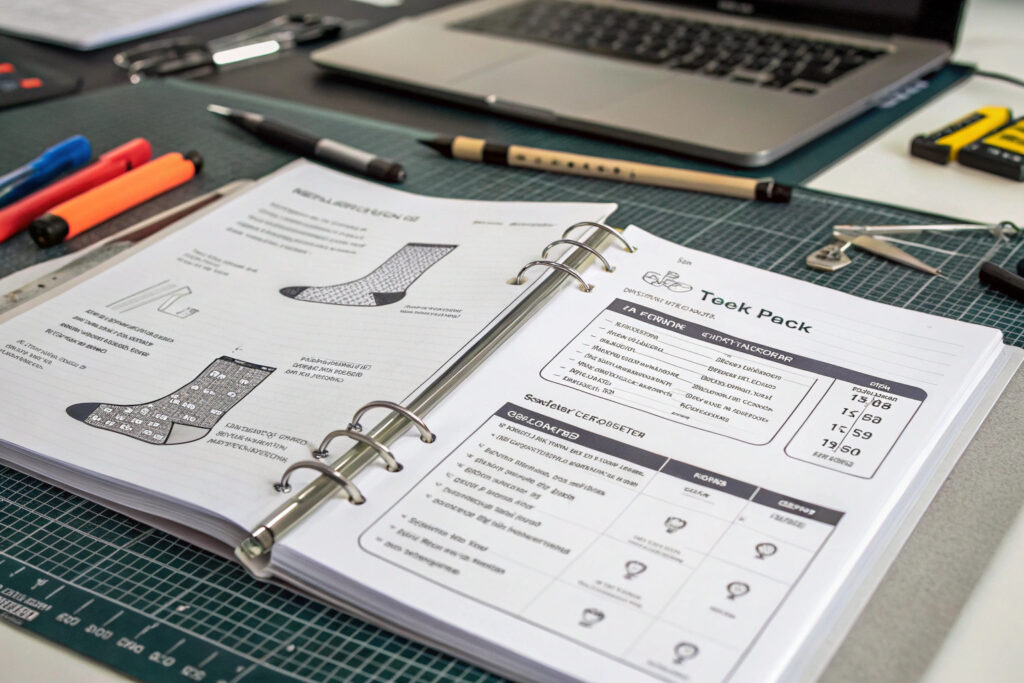

A tech pack for sock manufacturing is a detailed digital document that acts as the ultimate instruction manual for your sock production. It contains all the technical specifications, materials, design details, and packaging requirements needed to accurately manufacture your socks, ensuring your vision is perfectly translated into the final product without costly errors or delays. By providing a comprehensive blueprint, it bridges the communication gap between your design team and the factory, streamlining the entire process from sampling to bulk production.

Let's break down the essential components and steps to create a tech pack that ensures a smooth and successful manufacturing journey with your supplier.

What are the key components of a sock tech pack?

You have a brilliant sock design, but without a proper tech pack, it's just an idea. A missing detail can lead to the wrong fit, incorrect materials, or failed quality checks, costing you time and money.

A complete sock tech pack provides a single source of truth for your manufacturer. It eliminates guesswork and ensures every stakeholder is aligned on the final product's specifications, from design to delivery. This document is critical for obtaining accurate quotes, developing perfect samples, and maintaining consistency in bulk production.

Why is a detailed Bill of Materials (BOM) crucial?

The Bill of Materials (BOM) is the foundation of your sock. It lists every single component and material required. An inaccurate BOM leads to using the wrong yarns, elastics, or dyes, resulting in a product that doesn't meet your performance or comfort standards. For instance, specifying the exact blend of materials like organic cotton for breathability or Spandex for stretch is non-negotiable. It directly impacts the sock's functionality, durability, and cost. A precise BOM allows your supplier to source the correct materials upfront, preventing production halts and ensuring the final product matches your quality expectations, especially for specialized items like compression socks that require specific medical-grade fabrics.

How do construction details prevent manufacturing errors?

Construction details provide the "how-to" for building the sock. This includes the specific knitting techniques, stitch types, and seam finishes. Clearly defining whether you need a seamless toe closure or a linked toe can be the difference between a comfortable sock and one that causes blisters. Specifying the needle count for the knitting machine determines the fabric's density and feel. For athletic socks, you might require reinforced knitting at the heel and toe for extra durability. These details are vital for the factory's production team to execute your design correctly, ensuring the sock not only looks right but also performs and wears as intended over time.

How to specify materials and fabrics effectively?

Choosing the wrong material is a common and costly mistake. A vague fabric specification can lead to socks that are itchy, lack breathability, or shrink after the first wash, resulting in unhappy customers and product returns.

Effective material specification goes beyond just naming a fiber. It involves detailing the exact composition, yarn count, weight, and performance properties. This clarity enables your manufacturer to select or produce the ideal fabric that meets your design and functional goals, ensuring customer satisfaction.

What fabric properties should you test for?

Before finalizing your material choice, insist on comprehensive fabric testing. Key properties to verify include colorfastness to ensure the colors won't bleed during washing, and shrinkage rate to guarantee the sock maintains its size. For performance socks, moisture-wicking capability is essential to keep feet dry, and antibacterial treatment helps prevent odor. At GlobalSock, our CNAS-accredited lab rigorously tests all these properties, providing you with verified data and QR code tracking for each batch. This proactive step de-risks production and builds trust in your product's quality.

Why consider sustainable material options?

Today's consumers are increasingly eco-conscious. Integrating sustainable materials like recycled polyester (from plastic bottles), organic cotton (grown without pesticides), or Bamboo fiber (known for its softness and renewability) can significantly enhance your brand's appeal. Specifying these materials in your tech pack, along with relevant certifications like Oeko-Tex or GOTS, allows your supplier to prepare the correct eco-friendly fabrics from the start. This not only aligns your product with global sustainability trends, such as the EU eco-certifications but also often qualifies you for greener production lines, potentially reducing your environmental impact and appealing to a broader market.

What are the best practices for design and artwork?

A beautiful design can be ruined by poor technical execution. Unclear artwork files, incorrect color callouts, or miscommunication on placement lead to sampling cycles that never end, delaying your launch and frustrating your team.

Best practices in design and artwork presentation ensure your creative vision is communicated with precision. This involves using the right software, providing clean files, and giving explicit instructions for logos, patterns, and colors.

How to prepare print-ready artwork files?

Your artwork must be provided in a vector format (like AI or EPS) to ensure it can be scaled to any size without losing quality. Avoid using JPEGs or PNGs for logos, as they become pixelated when enlarged. Clearly specify the Pantone (PMS) codes for each color to ensure absolute color accuracy across different production runs. For complex patterns, especially on knee-high socks or over-the-knee socks, include a clear repeating pattern diagram and specify the exact placement on the sock template. This level of detail prevents misinterpretation and ensures the factory's graphic department can set up the printing or knitting machines correctly the first time.

What is the role of a grading chart?

A grading chart is a table that provides the precise measurements for every size in your product line, from ankle socks to crew socks. It details dimensions for key areas like the foot length, leg height, and cuff circumference for each size (e.g., S, M, L, XL). Without a grading chart, you risk inconsistent sizing, where a medium in one batch might fit like a small in another. This tool is fundamental for quality control and is used by the factory to program their knitting machines, ensuring every pair of socks you produce meets the expected size standards, which is critical for customer satisfaction and reducing returns.

How to streamline sampling and approval processes?

The sampling stage often becomes a bottleneck. Unclear feedback, subjective revisions, and a lack of a structured approval system can lead to endless sample rounds, missed deadlines, and strained supplier relationships.

Streamlining this process requires a clear, objective, and documented workflow. By establishing a formal sample approval procedure and using the tech pack as the benchmark for feedback, you can significantly reduce the number of sample cycles and accelerate your time to market.

How to provide effective sample feedback?

When evaluating a prototype sample, your feedback should be direct and tied directly to the tech pack. Instead of saying "the fit feels off," specify "the cuff elasticity measured at 12 cm does not meet the 10 cm specification in the grading chart." Reference the specific page and detail in the tech pack that requires correction. This objective, data-driven approach removes ambiguity and gives the factory's R&D team clear, actionable instructions. It transforms the process from a subjective debate into a collaborative problem-solving session, making it far more efficient.

Why set a clear limit for revision rounds?

It is standard practice to agree upon a maximum number of revision rounds (e.g., two rounds for prototyping and one pre-production sample) before starting. This sets clear expectations for both you and the manufacturer. It encourages you to consolidate all feedback into comprehensive, well-thought-out responses for each round, rather than sending piecemeal comments. For the factory, it allows for better production planning and resource allocation. This practice, a hallmark of an agile supply chain, prevents project drift and ensures your bulk order proceeds on schedule, protecting your launch dates.

Conclusion

A meticulously prepared tech pack is not just paperwork; it's the most powerful tool you have to ensure a smooth, efficient, and successful sock manufacturing process. It aligns your vision with the factory's execution, minimizes errors, and saves significant time and resources. By investing effort into creating a comprehensive tech pack that covers all key components, materials, design details, and approval workflows, you lay the groundwork for a high-quality product that meets your market's demands.

Ready to bring your sock designs to life with a manufacturing partner that values precision and clarity? At GlobalSock, we work with you to refine your tech packs for seamless production. Contact our Business Director Elaine today at elaine@fumaoclothing.com to discuss your next sock order and experience a partnership built on expertise and reliability.