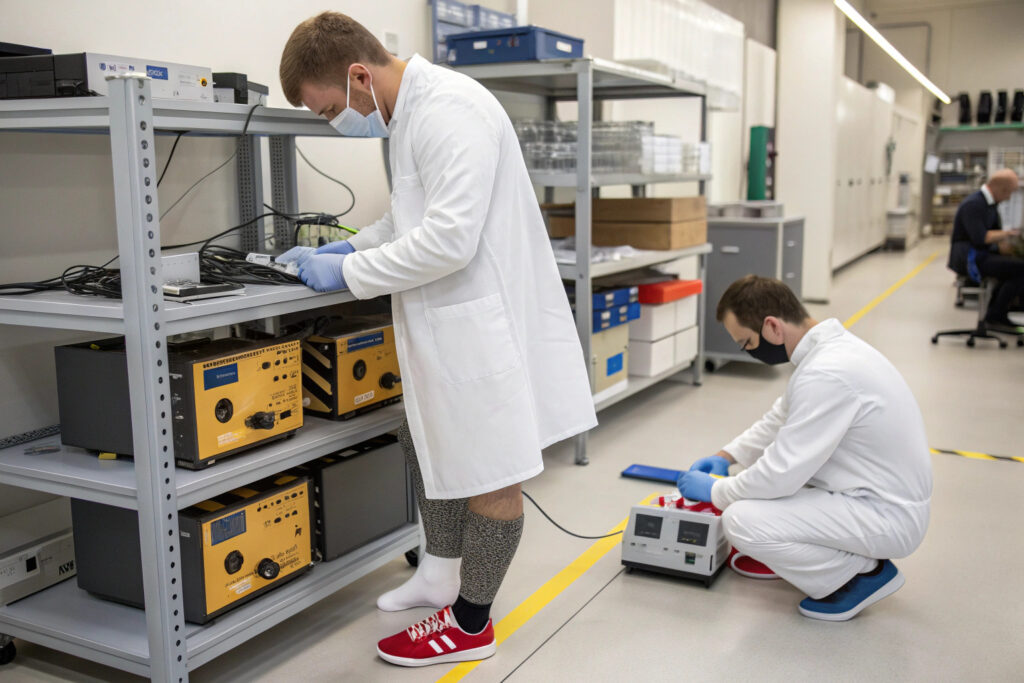

When managing an electronics manufacturing facility, even a small static discharge can cause serious damage to delicate microchips and circuit boards. Many purchasing managers know that anti-static socks are one of the simplest but most overlooked protective gears. The challenge is often how to source them correctly and ensure both quality and compliance.

Anti-static socks can prevent harmful static build-up, protect workers, and extend the life of sensitive electronics. Reliable sourcing means working with suppliers who understand both textile performance and international certifications.

If you want to find the right anti-static sock supplier, you need to know more than just product listings. You should understand material standards, certifications, logistics, and pricing strategies. Let’s dive deeper.

What Materials Are Best for Anti-Static Socks?

Anti-static socks are made from special fabrics designed to dissipate electrical charges. Choosing the right materials is the first step in effective sourcing.

The best anti-static socks use carbon fiber blends, conductive yarns, or polyester with embedded anti-static properties. These fabrics balance comfort, breathability, and electrostatic discharge protection.

Why Are Carbon Fiber Blends Popular?

Carbon fiber-infused fabrics are lightweight and durable. They create a continuous conductive path that releases static safely. Buyers often choose them because they combine effectiveness with comfort. For more information on carbon fiber textile applications, check resources like ScienceDirect or Textile World.

Are Polyester and Cotton Still Reliable Options?

Yes, polyester and cotton remain cost-effective, especially when treated with anti-static coatings. However, these treatments may fade after repeated washing. Buyers must confirm wash durability with suppliers. To explore more, visit CottonWorks and Polyester Fibers.

How to Verify Anti-Static Performance Standards?

Testing and certification ensure that anti-static socks meet international standards before use in electronics manufacturing.

Buyers should require certifications such as IEC 61340 or ANSI/ESD S20.20. Reliable suppliers provide test reports from accredited labs and track performance with QR codes or digital systems.

Which International Standards Should Buyers Know?

The most recognized standards are IEC 61340 and ANSI/ESD S20.20. These outline requirements for electrostatic discharge protection. Suppliers who align with these standards guarantee product compliance for global buyers.

How to Read and Trust Lab Test Reports?

Lab reports should include resistance values, wash cycle durability, and composition details. Buyers should check if the lab is accredited under CNAS or ISO. You can also cross-verify with third-party inspection firms like SGS.

What Logistics Challenges Should Importers Expect?

Even if you have the best anti-static socks, logistics challenges can disrupt your supply chain.

Importers must prepare for customs regulations, sailing schedules, tariff policies, and packaging standards. Choosing suppliers experienced in global logistics reduces delays and unexpected costs.

Are Tariffs a Problem for Anti-Static Socks?

Yes, tariffs can increase costs significantly, especially in the U.S. and EU. Some suppliers, like us, can ship through bonded warehouses or use alternative trade agreements to reduce tariff exposure. For updated tariff data, see USTR and European Commission Trade.

How Important Is Packaging for Sensitive Products?

Very important. Socks must be packaged in anti-static bags or protective cartons to prevent contamination during shipping. More insights are available from Packaging Europe and ISTA.

How to Choose the Right Supplier for Long-Term Success?

Selecting the right supplier is about more than price. It is about building a partnership that ensures consistent quality and innovation.

The best suppliers provide end-to-end services: fabric sourcing, product testing, bulk production, and logistics support. They also invest in R&D to improve anti-static performance and sustainability.

Should You Work With Factories or Trading Companies?

Factories offer direct production control, while trading companies provide broader sourcing flexibility. Both can be useful, depending on your business model. For guidance on supply chain models, explore Investopedia Supply Chain and Alibaba Supplier Guide.

What Role Does Sustainability Play in Supplier Selection?

Sustainability is increasingly important for buyers in Europe and America. Suppliers that use recycled fabrics or reduce carbon footprints have a competitive edge. Learn more at Sustainable Apparel Coalition and Textile Exchange.

Conclusion

Sourcing anti-static socks for electronics manufacturing requires more than just checking product catalogs. Buyers need to understand materials, verify certifications, prepare for logistics, and choose the right suppliers for long-term success.

If you are looking for a reliable partner, we at Shanghai Fumao can provide complete socks manufacturing and export services. From sampling and testing to packaging and customs clearance, we ensure every shipment meets international standards. You can contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your next bulk order and develop your customized anti-static sock solution.