Navigating the world of medical-grade compression socks presents unique challenges for buyers. You're dealing with strict medical standards, complex insurance reimbursement processes, and a market demanding both quality and compliance. For US procurement specialists and healthcare distributors, finding the right international manufacturer is crucial for profitability and patient satisfaction.

Sourcing compression socks covered by US health insurance requires partnering with manufacturers who understand FDA regulations, quality testing protocols, and insurance documentation requirements. The supplier must produce gradient compression garments with precise mmHg ratings, use certified materials, and provide necessary documentation to prove medical necessity for US patients and insurers.

This comprehensive guide will walk you through the critical steps of sourcing insurance-covered compression socks. We'll explore specific regulatory requirements, essential quality benchmarks, and documentation needed to ensure smooth reimbursement processes for your customers.

What are the FDA requirements for compression socks?

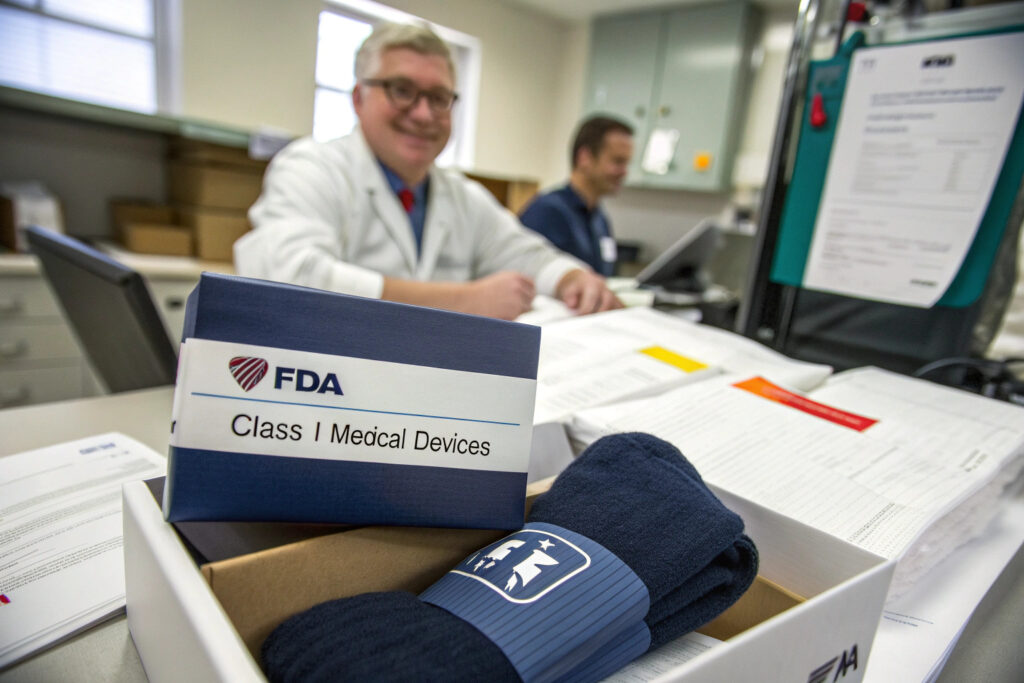

For compression socks to qualify for insurance coverage in the US, they must meet specific FDA requirements. The FDA classifies compression socks as Class I medical devices when marketed for medical purposes like managing venous disorders. This classification carries significant implications for manufacturing standards and documentation protocols.

The primary FDA requirement mandates manufacturing under Quality System Regulation, following Good Manufacturing Practices (GMP). This means factories must maintain documented quality management systems covering material sourcing, production processes, and final product testing. Manufacturers must provide evidence that their products consistently meet performance claims through rigorous testing protocols.

Why is 510(k) clearance critical for insurance reimbursement?

While many standard compression socks are exempt from pre-market notification, this exemption comes with strict conditions. When manufacturers claim their socks treat specific medical conditions like severe chronic venous insufficiency, or use novel materials, 510(k) submission becomes necessary. Working with manufacturers holding 510(k) clearance provides significant advantages when dealing with insurance companies.

How does gradient compression testing ensure efficacy?

Gradient compression represents the core function of medical compression hosiery, meaning highest pressure at the ankle gradually decreasing up the leg. This feature requires scientific measurement using specialized equipment like HOSY or TLS systems. Reputable manufacturers provide test reports verifying pressure profiles, which insurance companies may request to validate medical necessity.

How to verify manufacturer quality and certifications?

Verifying manufacturer quality claims represents the most critical step in de-risking your supply chain. In the compression sock industry, certifications serve as tangible proof of factory commitment to consistent quality and safety. For US buyers, finding partners with robust internal quality controls directly impacts brand reputation and insurance claim success.

The fundamental document to request is the ISO 13485 certificate, the international standard for quality management systems in medical device manufacturing. Manufacturers holding this certification demonstrate systematic approaches to design, production, and post-market surveillance. Evidence of physical product testing remains non-negotiable, including reports for durability, seam strength, colorfastness, and compression longevity.

What does an ISO 13485 certification guarantee?

ISO 13485 certification provides assurance that manufacturers operate as medical device companies rather than simple sock factories. This certification guarantees fully documented quality management systems covering all production aspects, including document control, corrective action management, and strict design processes. Certified factories demonstrate consistent ability to meet customer and regulatory requirements.

Why is material traceability important for US customs?

Material traceability has evolved from luxury to necessity for smooth US importation. With increasing scrutiny on product safety and origin, suppliers must provide clear chain of custody documentation for all raw materials. This proves particularly important for compression socks, where fabric composition must be accurately declared for customs compliance and tariff considerations.

What documentation is needed for insurance claims?

The compression sock journey extends beyond factory shipping to successful insurance claim reimbursement. Documentation provided by manufacturers plays pivotal roles in this final step. Incomplete or incorrect paperwork represents primary reasons for claim denials, making supplier documentation support crucial for business success.

The cornerstone document remains the Letter of Medical Necessity from prescribing physicians. However, manufacturers must supply detailed Certificates of Conformance or Statements of Compliance explicitly stating FDA compliance, specific compression levels, and conforming medical standards. Suppliers offering packaging with pre-printed HCPCS codes add significant value by demonstrating understanding of US billing ecosystems.

How can a CoC streamline the reimbursement process?

Certificates of Conformance serve as manufacturer sworn statements that product batches meet all specified requirements. For insurance auditors, robust CoCs represent key evidence, including product names, compression levels verified by testing, lot numbers for traceability, and clear statements of conformity with FDA regulations and relevant standards.

Why are HCPCS codes on packaging a game-changer?

HCPCS codes function as universal language for US healthcare billing systems. Having correct codes pre-printed on product packaging eliminates guesswork for dispensing providers and billing staff. This simple feature demonstrates manufacturer investment in understanding complete product journeys within US healthcare systems, preventing coding errors that lead to claim denials.

How to manage logistics and tariff costs?

In today's global supply chain environment, logistics efficiency and cost structure clarity separate profitable partnerships from problematic arrangements. For compression socks shipped from China to US markets, navigating tariffs, shipping schedules, and delivery timelines represents major pain points for buyers. Manufacturers with seasoned logistics capabilities transform this complexity into predictable, reliable processes.

Working with suppliers offering transparent Incoterms, preferably EXW or FOB, provides buyers with control over final shipping legs. Partners with established relationships with major freight forwarders often secure competitive rates and reliable vessel space. Since US tariffs on certain Chinese medical garments, confirming correct Harmonized System codes becomes essential for cost management.

What are the best shipping methods for medical hosiery?

Optimal shipping methods balance speed, cost, and reliability considerations. For large bulk orders, sea freight provides most cost-effective solutions despite longer transit times. For urgent or smaller batches, air freight offers speed at higher costs. Strategic approaches involve partnering with manufacturers offering flexible, diversified logistics plans including consolidated shipping options.

How can you avoid unexpected tariff expenses?

Avoiding tariff surprises begins with precise product classification. HS codes for compression socks prove critical, as misclassification leads to overpayment or customs complications. Professional manufacturers maintain expertise in correct product classification and provide detailed commercial invoices accurately describing goods, material composition, and declared values.

Conclusion

Sourcing compression socks for US markets that qualify for health insurance coverage represents multifaceted processes extending beyond price considerations. This demands strategic partnerships with manufacturers embodying regulatory expertise, uncompromising quality control, meticulous documentation, and agile logistics capabilities.

If you're seeking reliable partners for producing high-quality, insurance-ready compression socks, we stand ready to assist. Our expertise in medical-grade hosiery, combined with robust supply chains and transparency commitments, makes us ideal choices for your requirements. For information or discussion of specific needs, contact our Business Director Elaine at elaine@fumaoclothing.com.