Workplace safety is non-negotiable in high-risk industries. While companies invest heavily in flame-resistant (FR) coveralls and gloves, many overlook a critical element: protective socks. Ordinary socks can melt under extreme heat, causing severe burns and compromising worker safety. Sourcing the right fire-retardant socks is not just about compliance—it's about protecting lives.

The most reliable method to source fire-retardant socks for industrial safety compliance is to partner with a specialized manufacturer that offers certified FR materials, rigorous quality control testing, and comprehensive documentation to meet standards like NFPA 2112 and OSHA regulations. This ensures the socks provide genuine protection against thermal hazards and arc flashes. For procurement managers like Ron, this approach mitigates liability risks and ensures a trustworthy supply chain for essential safety gear.

Navigating the complexities of FR sock sourcing requires a clear strategy. Let's break down the key steps to ensure you procure socks that offer real protection and meet all necessary compliance benchmarks.

What Certifications Are Essential for Fire-Retardant Socks?

Certifications are the foundation of credible fire-retardant socks. They provide independent verification that the product has been tested and meets specific safety standards. Without proper certifications, you cannot be sure the socks will perform as expected in a hazardous situation.

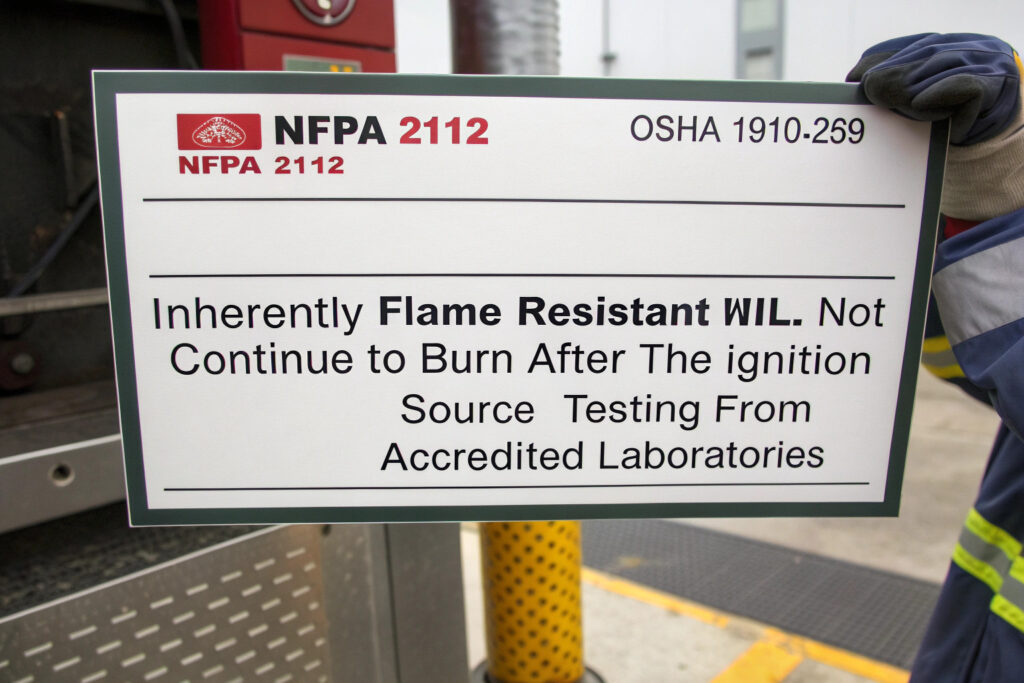

Essential certifications for fire-retardant socks include compliance with NFPA 2112 for flash fire protection and adherence to OSHA 1910.269 for electric arc exposure. These standards verify that the materials are inherently flame-resistant and will not continue to burn after the ignition source is removed. Socks should also have proof of testing from accredited laboratories, ensuring the claims are backed by scientific evidence.

Why is NFPA 2112 Compliance Non-Negotiable?

The NFPA 2112 standard is specifically designed for flash fire protection. It sets strict requirements for the fabric's thermal stability and resistance to ignition. Socks certified under this standard are made from inherently flame-resistant fibers like modacrylic, which are engineered to self-extinguish. This is crucial for workers in oil and gas, chemical plants, or any environment with a risk of sudden flash fires. Procuring socks without this certification leaves workers and the company vulnerable.

How Do International Standards Like OEKO-TEX Add Value?

While safety is paramount, comfort and skin health are also important for all-day wear. Certifications like OEKO-TEX Standard 100 ensure that the FR socks are free from harmful levels of more than 100 regulated and unregulated substances. This is critical because some FR treatments can involve chemicals. An OEKO-TEX certification guarantees that the socks are safe for prolonged skin contact, preventing dermatological issues and enhancing worker comfort without compromising the protective properties.

Which Materials Provide the Best Fire Retardant Protection?

The protective quality of a fire-retardant sock is determined by its core materials. Not all fabrics are suitable for FR applications. Understanding the difference between treated and inherent FR fibers is key to making a safe and durable sourcing decision.

The best materials for fire-retardant protection are inherent FR fibers like modacrylic, FR rayon, and aromatic polyamides (aramids). These fibers are engineered to be permanently flame-resistant at a molecular level, offering reliable protection that will not wash out or degrade over time. This contrasts with chemically treated cotton, which loses its FR properties after a certain number of launderings.

What Makes Modacrylic Blends a Top Choice?

Modacrylic is a synthetic copolymer known for its excellent inherent flame resistance, softness, and moisture-wicking properties. In our manufacturing, we often blend modacrylic with FR rayon to create a sock that is not only protective but also comfortable for long shifts. This blend offers a high level of thermal insulation and will not melt or drip onto the skin, a common hazard with some synthetic materials. The durability of this blend ensures the socks maintain their protective integrity through many industrial washes, providing long-term value.

Why are Aramid Fibers Used for High-Risk Applications?

For extreme heat and arc flash protection, aramid fibers like Nomex and Kevlar are the gold standard. These fibers are incredibly strong and thermally stable, offering protection in environments with high electrical risks or prolonged exposure to heat. Socks incorporating aramid fibers provide superior resistance to abrasion and cutting, adding an extra layer of durability. While the cost is higher, this investment is non-negotiable for workers in utilities, electrical transmission, and firefighting.

How to Verify FR Sock Quality and Durability?

Certifications and materials mean little if the socks fail in the field. A robust verification process is essential to ensure the FR socks you source will perform consistently and last through the required wear and wash cycles.

To verify FR sock quality and durability, partner with a manufacturer that has an in-house CNAS-accredited lab for consistent batch testing. Key tests include vertical flame testing for flame resistance and standardized wash tests to ensure the FR properties are permanent. This due diligence protects your company from the risks of substandard protective equipment.

What On-Site Lab Tests Guarantee Performance?

A manufacturer with its own testing facilities, like our CNAS-accredited lab, can provide the highest level of quality assurance. The most critical test is the vertical flame test (ASTM D6413), which measures after-flame time, char length, and whether the material drips when exposed to a direct flame. By conducting this test on every production batch, we guarantee that each pair of socks meets the specified FR standards before shipping. This eliminates the uncertainty of third-party testing delays and ensures consistent quality.

How Many Wash Cycles Should FR Socks Endure?

The durability of FR properties is measured by their lifespan. Inherent FR socks should maintain their protection for the entire wearable life of the garment. We subject our socks to accelerated laundering tests (ISO 6330) to simulate years of industrial washing. A high-quality FR sock should withstand 50-100+ washes without any degradation in its flame-resistant performance. This data should be readily available from your supplier and is a key factor for procurement managers calculating the total cost of ownership.

What is the Lead Time for Bulk FR Sock Orders?

In industrial sourcing, timeliness is critical. A delay in receiving FR socks can halt operations or force workers to use non-compliant gear. Understanding the manufacturing lead times and supply chain resilience is a vital part of the sourcing process.

The lead time for bulk FR sock orders typically ranges from 30 to 45 days, depending on the order complexity and customization. A manufacturer with an agile supply chain, like ours in the Keqiao textile cluster, can often expedite this process due to local access to specialized FR yarns and efficient production lines. This speed is crucial for maintaining inventory and avoiding project delays.

How Can You Accelerate the Sampling Process?

The development speed of a manufacturer sets the tone for the entire project. We have optimized our process to deliver FR sock samples within one week. This agility comes from our deep partnerships with local FR yarn suppliers and our in-house R&D team that is well-versed in safety standards. By providing a quick sample, you can conduct your own compliance checks and make design adjustments without delaying your procurement timeline. This directly addresses the pain point of inefficient processes that buyers like Ron often face.

What Logistics Solutions Ensure On-Time Delivery?

A reliable manufacturer offers more than just production; they offer a complete logistics solution. Our integration with the "Silk Road Keqiao" initiative provides access to efficient overseas warehousing and customs clearance channels. This established network helps mitigate the risks of sailing schedule volatility and ensures your bulk order of FR socks reaches your U.S. warehouse on time, every time. This supply chain security is a core component of a trustworthy partnership.

Conclusion

Sourcing fire-retardant socks for industrial safety is a serious responsibility that requires a meticulous approach. By prioritizing certified inherent FR materials, verifying quality through accredited lab testing, and partnering with a manufacturer that guarantees both speed and supply chain resilience, you can fully protect your workforce and ensure regulatory compliance. This strategy turns a basic procurement task into a critical investment in human safety and operational integrity.

If you are looking to source or develop your own line of certified, high-quality fire-retardant socks, we are here to assist. Our team specializes in creating compliant safety wear for global industrial brands. For a direct conversation about your production needs, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's ensure workplace safety together.